The AC series Self-compensation shock absorber are designed with high hardness stainless steel shaft, the shock absorber has better impact and corrosion resistance, and it can work under adverse conditions. The compact structure leads to high max. absorbed energy, and the special oiling process leads to stable shock absorbing. The outer body of integrated structure is treated by QPQ, which has optimum corrosion and wear resistance and can withstand high pressure; it is easy to install and adjust for all threaded outer body which has good heat dissipation.

◈Body material: Iron

◈Stroke:20 mm

◈Working temperature:-10 ~+80 ℃

◈ Impact speed: Middle speed

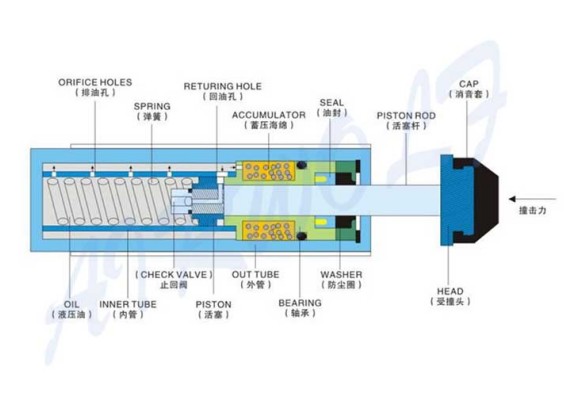

Principle

When piston rod is impacted, it will

drive piston to press oil in inner tube. Oil will be pressed out through

orifice holes of inner tube. At the same time, the oil returns to inner

tube through returning hole of inner tube.

After outside force vanishes, spring makes piston rod immediately return to its position. Oil will return to inner tube through check valve. Then shock absorber will return to be ready position waiting for next action.

Attention

1. It is strictly prohibited to knock or collide the shaft, which may easily lead to bending of the shaft.

2.

The surface of the shaft should not be covered with sewage or dirty

oil, and the shaft must operate in a clean environment.Otherwise, it

will increase the probability of product leakage and reduce the service

life of the product.

3. It is strictly prohibited to spray paint on

the pipe teeth and axis, otherwise it will affect the heat dissipation

effect and oil leakage.

Feature

| Model | Stroke (mm) | Max. Impact Speed (m/s) |

| AC1410-2 | 10 | 2 |

| AC1420-2 | 20 | 2 |

| AC1425-2 | 25 | 2 |

| AC2020-2 | 20 | 2 |

| AC2030-2 | 30 | 2 |

| AC2050-2 | 50 | 2 |

| AC2525-2 | 25 | 2 |

| AC2550-2 | 50 | 2 |

| AC3660-2 | 60 | 2 |

Delivery

1. If the products we have in store, we will send it out ASAP after payment.

2.

If the products which were customized, we will complete the production

within a specified period of time, and send it out the first time, we

can promise it.

3. We have a variety of ways to deliver goods,

usually DHL, Fedex, TNL will be normal ways, If you require use of a

courier, we can do it.

4. Also we can send by your delivery acount if you want.

Samples

You

can send a sample to customize the products, we have many engineers can

help it; If you want a product of mine, but you are not sure if it's

what you want, so you can ask for a sample from me, it will be free.

After-sale service

We can provide a series of after-sale service, such as product introduction, mounting, debugging, technical support and so on.

Copyright © 2025 LV-pneumatic. | All Rights Reserved