The RBC series Self-compensation shock absorber are designed with high hardness stainless steel shaft, the shock absorber has better impact and corrosion resistance, and it can work under adverse conditions. The compact structure leads to high max. absorbed energy, and the special oiling process leads to stable shock absorbing. The outer body of integrated structure is treated by QPQ, which has optimum corrosion and wear resistance and can withstand high pressure; it is easy to install and adjust for all threaded outer body which has good heat dissipation.

◈Ambient temperature range (°C): –10 to 80 (No freezing)

◈Collision speed (m/s):0.05 to 5.0

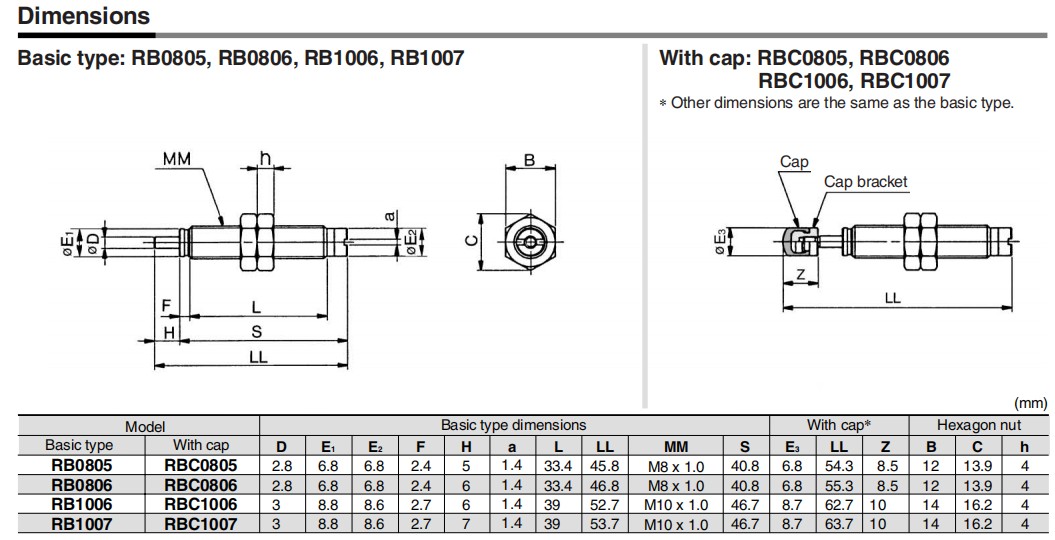

◈ Stroke absorption (mm):12

◈Max. energy absorption (J): 19.6

◈Max. operating frequency ∗(cycle/min):45

◈Max. allowable thrust (N):814

Specifications and operational instructions

Ensure that the collision speed, thrust, operation cycle, the ambient temperature

and atmosphere fall within the specifications.

∗Be aware of the min. installation radius in the case of rotating impacts.

Attention

1. It is strictly prohibited to knock or collide the shaft, which may easily lead to bending of the shaft.

2.

The surface of the shaft should not be covered with sewage or dirty

oil, and the shaft must operate in a clean environment.Otherwise, it

will increase the probability of product leakage and reduce the service

life of the product.

3. It is strictly prohibited to spray paint on

the pipe teeth and axis, otherwise it will affect the heat dissipation

effect and oil leakage.

Copyright © 2025 LV-pneumatic. | All Rights Reserved