Industrial pneumatic component introduction:

This artiticle from Airwolf factory mainly goes through pneumatic component industrial knowledge, emcompassing what it is, pros and cons of pneumatic product application, development history of pneumatic part, how to deal with it when it comes to troubleshooting.

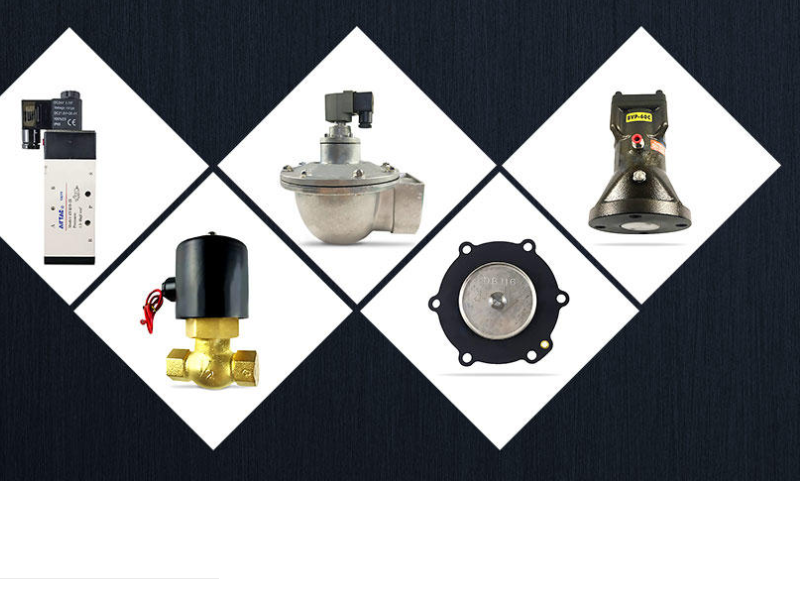

A pneumatic component that does work through pressure of a gas or the force generated by expansion, converts the elastic energy of compressed air into kinetic energy, embodied by pneumatic cylinder, pneumatic motor, pneumatic steam engine and so on. Pneumatic product is a form of power transmission, also functions as an energy conversion device operated by using gas pressure to transfer energy.

Advantages

1.Pneumatic device is simple in structure, light in weight, succinct in installation and maintenance. The medium is air, compared with the hydraulic medium, its medium is not easy to burn to safety and security of pneumatic product application.

2.Working medium is inexhaustible air, air itself does not cost money. Exhaust treatment is simple, does not pollute the environment and at low cost.

3.Adjustment of output force and working speed are both very easy. Pneumatic cylinder movement speed is generally less than 1M/S, faster than the hydraulic and electrical mode of movement speed.

4.High reliability and long service life. The number of effective actions of electrical components is about one million times, and the life of the general solenoid valve is more than 30 million times, some good quality pneumatic valves more than 200 million times.

5.Make use of compressibility of air to store energy and realize centralized air supply. It can release energy in short time to obtain high speed response in intermittent movement. Buffering can be implemented. Strong adaptability to shock load and overload. Under certain conditions, the pneumatic device has self - retaining capability.

6.Full pneumatic control with fire-resistant, explosion-proof, moisture-proof ability. Compared with hydraulic mode, pneumatic mode can be used under high temperature occasions.

7. Compressed air can be centrally supplied and transported long distance.

Disadvantages

1.Due to the compressibility of air, the operating speed of pneumatic cylinder is susceptible to changes in load. The gas-liquid linkage can overcome this defect.

2.When the cylinder moves at low speed, its stability at low speed is not as good as that of the hydraulic cylinder due to the large proportion of friction in thrust.

3.Although in many applications, the output force of the pneumatic cylinder can meet the working requirements, its output force is smaller than that of hydraulic cylinder.

Pneumatic component technology lies in compressed air as a medium to drive and control machinery. Because of its energy-saving, pollution-free, high efficiency, low cost, safe and reliable, simple structure and other advantages, widely used in all kinds of machinery and production lines.

In the past, each factory designed, manufactured and maintained the pneumatic system and its components on the production line of automobiles and tractors.

Maintenance of pneumatic component product

If not properly maintained, a set of pneumatic components equipment will reduce the life of the equipment, provided serious failure of the security risks are not to be underestimated, then how to maintain a good set of pneumatic components equipment?

1. To ensure the correct substitute air supply system: inlet pressure at the tool inlet (non-air compressor outlet pressure) is generally 90PSIG(6.2Kg/cm^2), if too high or too low, it will damage the tool performance and life of pneumatic components. The intake must contain sufficient lubricating oil for the pneumatic motor inside the tool to be fully lubricated (a piece of white paper can be placed at the tool exhaust to check for oil stains, normal for oil stains). Intake must not contain water, if compressed air is not air dryer, it is not appropriate.

2. It is not allowed to operate pneumatic product after removing the parts of the tool arbitrarily, except that the safety of the operator will be affected and the tool will be damaged.

3. If the tool has some faults or fails to reach the original function after use, it cannot be used again, it should be checked immediately.

4. Use all kinds of pneumatic tools in accordance with the safety regulations and instructions.

5. Choose the appropriate tools to work, if pneumatic tools are too big, it will be easy to cause work injury, on the contrary, if too small, it will be easy to damage pneumatic tool .

6. Check and maintain pneumatic tools regularly (about once a week), add butter to the rotating parts such as bearings, and smear oil on pneumatic motors.

Development

Application expansion of pneumatic components is a symbol of the development of pneumatic industry. The application of pneumatic components is mainly in two aspects: maintenance and matching. In the past, the sales of domestic pneumatic components should be used for maintenance. In recent years, the sales share of direct supporting equipment has been increasing year by year. Domestic applications of pneumatic components spans from tens of millions of yuan worth of metallurgical equipment to only 1~ 200 yuan chair. Specially, developed pneumatic components are used in railway turning switches, locomotive wheel and rail lubrication, train brakes, street cleaning, lifting equipment in special workshops and military command vehicles. This shows that pneumatic technology has "penetrated" into all walks of life, and currently is still scaling up.

Although China's pneumatic industry has reached a certain scale and technical level, it lags far behind the international advanced level. The output value of pneumatic products in China only accounts for 1.3% of the world's total output value, which is only 1/21 of that of the United States, 1/15 of That of Japan and 1/8 of that of Germany. This is not in keeping with a country of more than a billion people. Look from breed, a Japanese pneumatic product company has 6500 breed, our country has it only 1/5. The gap between pneumatic product performance and quality level is also large.

Pneumatic technology is increasingly used in various industries due to the automatic assembly and automatic processing of small, special items of equipment, the original traditional pneumatic components are constantly improve performance, and gradually develops to meet the market requirements of new products, make the pneumatic components of the varieties increase, its developing tendency mainly has the following several aspects:

In the manufacturing industry of electronic components and pharmaceuticals, the small size of the workpiece is bound to limit the size of pneumatic components, and miniaturization and lightness are the first development direction of pneumatic components. A subminiature solenoid valve with thumb size and effective cross-sectional area of 0.2mm2 has been developed abroad. It is more ideal to develop components with small dimensions and large flow. To this end, the same size of the valve, flow has been increased by 2~3.3 times. There is a series of small solenoid valves, the body width is only 10mm, effective area up to 5mm2; The width is 15mm and the effective area is 10mm2.

Foreign solenoid valve power consumption has reached 0.5W, and it will be further reduced to adapt to the combination with microelectronics. Air source treatment components, most of the domestic and foreign use of building block structure, not only compact size, and combination, maintenance is very convenient. In order to improve the positioning accuracy of the cylinder, the cylinder with brake mechanism and servo system is more and more widely used. The peumatic cylinder with servo system can achieve positioning accuracy of ±0.1mm even if the air supply pressure and load changes.

In the international exhibition, there are many pneumatic cylinders of various special-section and piston rods. Since the piston rod does not rotate, this kind of pneumatic cylinder can maintain a certain precision without additional guide device when applied to the main engine. In addition, many pneumatic cylinders with various guide mechanisms and pneumatic cylinder sliding components are also developed, such as pneumatic cylinder with two guide rods, double piston rod double cylinder cylinder, etc.

Cylinder shape is not limited to round, but square, shape, or other shapes, in the profile pneumatic cylinder has opened the guide groove, sensor and switch installation slot for more convenient installation and use of cylinder.

In order to facilitate users and meet the needs of the market, a variety of small pneumatic systems composed of multiple pneumatic components and equipped with control devices have been developed. For example, a component for moving small items is a combination of two pneumatic cylinders with a guide along the X-axis and the Z-axis. The assembly can carry 3kg weight, equipped with solenoid valve and program controller, compact structure, small space, adjustable travel. Another example is the loading and unloading module, which has seven modules with different functions. It can complete the loading and unloading operation on the precision assembly line, and different modules can be combined arbitrarily according to the operation content. There is also a manipulator is a small shape and can change the swing Angle of the swing cylinder and chuck assembly, chuck head has a number of chucks optional.

With the combination of electronic technology, a large number of sensors are used, and pneumatic components are intelligent. The cylinder with switch has been widely used in China, the switch will be smaller in volume, higher in performance, and can be embedded into the cylinder block; Some also have two color display, can show the position error, make the system more reliable. Using sensors to replace the flow meter and pressure gauge can automatically control the flow rate and pressure of compressed air, which can save energy and ensure the normal operation of the device. Pneumatic servo positioning system products have entered the market. The system adopts three-position five-way pneumatic servo valve, compares the detection data of the predetermined positioning target and position sensor, and implements negative feedback control. When the maximum cylinder speed is 2m/s and the stroke is 300mm, the positioning accuracy of the system is ±0.1mm. A new type of intelligent solenoid valve has been successfully trial-produced in Japan. The valve is equipped with a logic circuit with a sensor. It is the product of pneumatic components and optoelectronics technology. It can directly accept the signal of the sensor. When the signal meets the specified conditions, it can complete the action by itself and achieve the control purpose without passing through the external controller. It has been used in the object conveyor belt, can identify the size of carrying objects, so that the large pieces directly down, small pieces split.

According to the international standards of pneumatic technology in recent years, the standards not only put forward interchangeability requirements, but also emphasize safety.

Many use occasions of pneumatic components, such as rolling mill, textile assembly line, etc., can not be interrupted during working hours because of the quality of pneumatic components, otherwise it will cause huge losses, so the reliability of pneumatic components work is very important. In Marine ships, the use of pneumatic components, but can enter the field of pneumatic components factory is not many, the reason is that its reliability requirements for pneumatic components is particularly high, must pass the relevant international machinery certification.

In order to improve the production efficiency of production equipment, it is imperative to improve the working speed of executive components. The cylinder working speed in China is generally below 0.5m/s. According to the prediction of Japanese experts, in five years, the working speed of most cylinders will increase to 1~2m/s, and some require up to 5m/s. The improvement of cylinder working speed requires not only the improvement of cylinder quality, but also the corresponding improvement in the structure, such as the configuration of oil pressure absorber to increase the buffering effect. The response time of the solenoid valve will be less than 10ms and the service life will be increased to more than 50 million times. There is a gap sealed valve in the United States, because the valve core suspended in the body, do not contact each other, without lubrication, life up to 200 million times.

Oil-free lubrication technology is widely used to meet some special requirements. Due to environmental pollution and the requirements of electronic, medical, food and other industries, oil is not allowed in the environment, so oil-free lubrication is the development trend of pneumatic components, and oil-free lubrication can simplify the system. Oil mist on the European market has been eliminated products, generally do without oil lubrication. In addition, in order to satisfy certain.

Special requirements, deodorization, sterilization and precision filters are being developed, filtration accuracy has reached 0.1~0.3 m, filtration efficiency has reached 99.9999%.

Pneumatic seals made of polytetrafluoroethylene as the main body can be heat (260℃), cold (-55℃) and wear-resistant, its use occasions are increasing.

In order to improve the quality, new technologies such as vacuum die casting and hydrogen/oxygen explosion deburring are gradually popularized in the manufacturing of pneumatic components. It is easy to maintain, repair and use. The use of sensors to realize pneumatic components and systems with fault prediction and self-diagnosis functions are being studied abroad.

From the above development direction of pneumatic technology, we can see that we have a lot of work to do in the development of pneumatic products. Any pneumatic component factory, even if its size is not large, as long as a breakthrough in one aspect, and maintain the leading technology, can occupy a place in the market, in the fierce competition for survival and development.

The main component of the life-saving thrower is a gun body with a built-in cylinder and a folding gun butt, which is a typical application of pneumatic products. It plays a very important role in water rescue and land rescue.

The market of pneumatic components moves towards the development direction of pneumatic components: higher safety and reliability. According to the international standards of pneumatic technology in recent years, the standards not only require interchangeability, but also emphasize safety. The pressure of tube joint, air source treatment shell and other withstand tests should be increased to 4-5 times of the service pressure, and the withstand time should be increased to 5-15 min. The tests should also be carried out at high and low temperatures. If these international standards are implemented, it is difficult for domestic cylinder, end cap, air source treatment casting and pipe joint to meet the standard requirements. In addition to the pressure test, the structure has also made some provisions, such as the air source treatment of transparent shell outside the provisions to add metal protective cover.

Troubleshooting: Cylinders can also malfunction due to improper installation and use.

Cause analysis & elimination

1) External leakage:

Piston rod installation eccentricity: Start reinstallation so that piston rod is not subject to eccentricity & lateral load.

Insufficient lubricant supply: Check the lubricator for malfunction.

Piston seal wear: Replace the seal.

Impurities on the mating surface of the piston rod bearing: Clean to remove impurities, install and replace the dust cover.

The piston rod has scratches: replace the piston rod.

2) Internal leakage:

Poor lubrication: Check if the lubricator is malfunctioning

Piston is stuck and the matching surface of piston is defective: reinstall and adjust so that piston rod is not subject to eccentricity & lateral load

Impurities squeeze into the sealing surface: remove impurities & use purified compressed air.

3) Insufficient output force & unstable movement:

Poor lubrication: check if the lubricator is malfunctioning

Piston or piston rod stuck: re-install and adjust to eliminate eccentric lateral load

Insufficient air flow: increase the diameter of the connection or pipe joint

There are condensed water impurities: pay attention to use purified dry compressed air to prevent water condensation

4) Poor buffering effect:

Buffer seal wear: replace the seal

Adjusting screw damaged: replace adjusting screw

The speed of the cylinder is too fast: pay attention to whether the buffer mechanism is suitable

5) Damage: Damaged piston rod & damaged cylinder head

With eccentric lateral load: eliminate eccentric lateral load

The piston rod is under impact load: the impact cannot be added to the piston rod

The speed of the cylinder is too fast: set a buffer device

Buffer mechanism does not work: Buffer mechanism is set in external or loop