Solenoid valve is a valve to control industrial equipment and fluid automation basic components, it belongs to one of actuators, but not limited to hydraulic, pneumatic parts. Solenoid valve, specifically, is to serve for industrial control systems to adjust its direction, flow, speed, and other parameters of medium. Solenoid valves can be fitted with different circuits to achieve the desired control so that control accuracy and flexibility can toe the line as commanded. There are many kinds of solenoid valves, different solenoid valves in control system of different positions bring themselves to full play, in which, one-way valve, safety valve, direction control valve, speed control valve are common solenoid valves .

Working principle of solenoid valve

Solenoid valve has closed cavity with different open holes located in different position, each hole is to connect different tubings, both sides are two electromagnets, which face magnet coil electricity body which side will be attracted.

Through to control the movement of solenoid valve to open or close the different discharge of oil hole, and oil hole is always open, hydraulic fluid will enter the different oil drain, and then through the oil pressure to push the cylinder piston, piston drives the piston rod, piston rod drive mechanism. In this way, mechanical motion is controlled by controlling the current of electromagnet.

Classification of solenoid valve

Direct solenoid valve

Principle: When electrified, the electromagnetic force generated by electromagnetic coil will lift the closing part from seat and the solenoid valve will open. When the power is off, the electromagnetic force disappears, the spring presses closing part on seat, and solenoid valve is closed.

Feature: it can work normally in vacuum, negative pressure and zero pressure, but the diameter is generally not more than 25mm.

Step-by-step solenoid valve

Principle: when the inlet and outlet have no pressure difference, after electrization, the electromagnetic force directly pilot small valve and main valve close part in turn up, the valve opens. When the pressure of the main valve lower chamber rises, the pressure of the upper chamber drops, so as to use the pressure difference to push the main valve upward; When power is off, the pilot valve uses spring force or medium pressure to push the closing part and move downward to close solenoid valve.

Feature: this solenoid valve could function under zero pressure difference or vacuum, high pressure due to large power, it must be installed horizontally.

Pilot solenoid valve

Principle: when electrified, the electromagnetic force opens the pilot hole, and the pressure in the upper chamber drops rapidly, forming a high and low pressure difference around the closing part. The fluid pressure pushes the closing part to move upward, and the valve is opened. When the power is cut off, the spring force will close the pilot hole, inlet pressure through the bypass hole rapidly chamber in the valve close around the lower low high pressure difference, fluid pressure to push the closure of the parts down, close the valve.

Feature: under high upper limit of fluid pressure range, pilot solenoid valve can be arbitrarily installed (customized solenoid valve ) but must meet the fluid pressure differential conditions.

On the basis of valve structure and material, principle, solenoid valve could be divided into six small categories: direct acting diaphragm structure, step by step direct acting diaphragm structure, pilot diaphragm structure, direct acting piston structure, step by step direct acting piston structure, pilot piston structure.

Classified according to function, solenoid valve could be classified into electromagnetic valve: water solenoid valve, low temperature steam gas solenoid valve, solenoid valve, fire solenoid valve, solenoid valve, ammonia gas solenoid valve, solenoid valve, liquid micro electromagnetic valve, electromagnetic pulse valve, hydraulic solenoid valve, open solenoid valve, solenoid valve for oil use, dc electromagnetic valve, high pressure solenoid valve, explosion-proof solenoid valve.

According to raw materialm, solenoid valve can be divided into three categories:

1)Stainless steel solenoid valve is the most common solenoid valve product, stainless steel material brings good quality, stable work, therefore, stainless steel solenoid valve has been widely favored.

This series of products are widely used in textile, printing, chemical, plastic, rubber, pharmaceutical, food, building materials, machinery, electrical appliances, surface treatment and other production and scientific research departments, as well as bathroom, canteen, air conditioning and other People's daily life facilities.

2) Brass solenoid valve: some users with low requirements will choose brass solenoid valve products. This kind of solenoid valve products are relatively low in price and suitable for ordinary working environment.

This series of products are generally suitable for liquid, water, gas, hot water, oil, gas and other media.

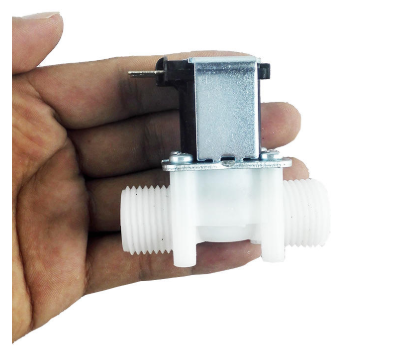

3)Plastic electromagnetic valve

In some special place of work, and the use of special medium in the solenoid valve, such as acid, alkaline medium environment, brass and stainless steel solenoid valve products are easy to corrode, so using a special material (engineering plastics, PVC, CPVC, UPVC, ABS or ptfe, etc.) made of plastic electromagnetic valve on the corrosion resistance of outstanding.

This series of products is suitable for drinking water, all kinds of untreated sewage, rainwater, sea water and all kinds of acid, alkali and salt solutions, organic solvents.

Solenoid valve selection should first follow the safety, reliability, applicability, economic four principles, followed by six aspects of the field conditions (namely pipeline parameters, fluid parameters, pressure parameters, electrical parameters, mode of action, special requirements).

Selection basis:

1. Select the right solenoid valve according to the pipeline parameters: size specification (DN), interface mode

1) Determine the diameter (DN) of the pipeline in accordance with the on-site internal diameter or flow requirements;

2) Interface mode. Generally, >DN50 choose flange interface. If ≤DN50, it can be freely selected according to user needs.

2. According to the fluid parameters to choose the solenoid valve: material, temperature group

1) Corrosive fluid: corrosion resistant solenoid valve and all stainless steel should be selected; Edible super clean fluid: food grade stainless steel solenoid valve should be selected;

2) High temperature fluid: choose solenoid valve made of high temperature resistant electrical materials and sealing materials, and choose type of piston structure;

3) Liquid state: large to gaseous, liquid or mixed state, especially when the diameter is larger than DN25, it must be distinguished;

4) Fluid viscosity: usually below 50cSt can be arbitrarily selected, if the value is more than this, high viscosity solenoid valve should be selected.

3. according to the pressure parameters to choose the solenoid valve: principle and structure varieties

1) Nominal pressure: This parameter is the same as other common valves and is determined according to the nominal pressure of the pipeline;

2) Working pressure: if the working pressure is low, the principle of direct-acting or step-by-step direct-acting must be adopted; When the minimum working pressure difference is above 0.04mpa, direct acting, step by step, pilot can be selected.

4. Electrical selection: AC220V and DC24 should be preferred for voltage specification.

5, according to the length of continuous working time to choose: normally closed, normally open, or sustainable power

1) When the solenoid valve needs to be opened for a long time, and the lasting time is more than the closing time, the normally open type should be selected;

2) If the opening time is short or the opening and closing time is not long, select the normally closed type;

3) However, for some working conditions used for safety protection, such as furnace and kiln flame monitoring, the normally open type should not be selected, but the type that can be powered on for a long time should be selected.

6. Select auxiliary functions according to environmental requirements: explosion-proof, check, manual, waterproof fog, water shower, diving.

Security:

1) Corrosive medium: Plastic King solenoid valve and all stainless steel should be selected; Isolation diaphragm type must be used for strongly corrosive medium. Neutral medium, it is also appropriate to choose copper alloy as the solenoid valve shell material, otherwise, valve shell often rust chip off, especially the occasion of infrequent action. Ammonia valve can not use copper.

2) Explosive environment: products with corresponding explosion-proof grade must be selected. Waterproof and dust-proof products should be selected for outdoor installation or dust multi-occasions.

3)The nominal pressure of the solenoid valve should exceed the maximum working pressure in the tube.

Applicability:

1) Different types of solenoid valves shall be selected in the state of gas, liquid or mixture;

2) Products with different media temperatures and specifications, otherwise the coil will be burned off and the seals will age, seriously affecting the life;

3) Medium viscosity, usually below 50cSt. If this value is exceeded, when the size is greater than 15mm, use multi-function solenoid valve; For sizes less than 15mm, use high viscosity solenoid valves.

4) Medium cleanliness is not high should be installed in front of the solenoid valve backflush filter valve, low pressure, can choose the direct action diaphragm type solenoid valve;

5) If the medium is directional circulation and does not allow backflow, two-way circulation is required;

6) Medium temperature should be selected in the allowable range of the solenoid valve.

Service life of solenoid valve

Solenoid valve used to the damage of the main parts, can not carry out normal reversing and reset action, or use its main performance indicators deteriorated significantly more than the number of reversing experienced by the specified indicators.

Common failure

Solenoid valve is composed of a solenoid coil and a magnetic core and is a valve body containing one or more holes. When the coil is energized or powered off, the core operation will cause the fluid to pass through the body or be cut off in order to change the direction of the fluid. Solenoid valve electromagnetic components by fixed iron core, moving iron core, coil components; The valve body is composed of slide valve core, slide valve sleeve, spring base, etc. The solenoid coil is directly mounted on the valve body and the valve body is enclosed in the sealing tube, forming a simple and compact combination. We in the production of commonly used solenoid valves have two three, two four, two five. Here first talk about the meaning of two: for the solenoid valve is live and lose power, for the control of the valve is on and off.

Failure of solenoid valve will directly affect the action of switching valve and regulating valve, the common failure of solenoid valve does not act, should be checked from the following aspects:

1. Solenoid valve wiring head loose or fall off, solenoid valve not electric, can tighten the wire head.

2. Solenoid valve coil burned out, can be removed solenoid valve wiring, with a multimeter measurement, if open, then solenoid valve coil burned out. The reason is that the coil is damp, resulting in bad insulation and magnetic leakage, resulting in excessive current in the coil and burnt out, so to prevent rain into the solenoid valve. In addition, the spring is too hard, the reaction force is too large, the number of turns of the coil is too small, not enough suction can also cause the coil to burn out. In case of emergency, the manual button on the coil can be set from the "0" position in normal operation to the "1" position to make the valve open.

3. Solenoid valve stuck: solenoid valve sliding sleeve with the valve core clearance is very small (less than 0.008mm), is generally a single assembly, when there are mechanical impurities or oil is too little, it is easy to get stuck. The treatment method can be used to poke the steel wire through the hole in the head to make it bounce back. The fundamental solution is to remove the solenoid valve, take out the spool and spool sleeve, with CCI4 cleaning, so that the spool in the valve sleeve action flexible. Attention should be paid to the assembly sequence and external wiring position of each component during disassembly in order to reassemble and wiring correctly, and check whether the oil spray hole is blocked and whether the lubricating oil is enough.

4. Air leakage: air leakage will cause insufficient air pressure, making it difficult to open and close the forced valve, the reason is that the seal gasket damage or slide valve wear caused by several cavities. When dealing with the solenoid valve failure of the switching system, should choose the appropriate time, such as the solenoid valve in the loss of power when the processing, if not finished in a switching clearance, the switching system can be suspended, calmly processing.

Common application

Solenoid valve is the magnetic force generated after the solenoid coil is energized to overcome the pressure of the spring to drive the spool action, a solenoid coil, simple structure, cheap price, can only realize the switch.

1. Solenoid valve: used for liquid and gas pipeline switch control, is two DO control.

Generally used for small pipe control.

2.Solenoid valve: can only be used as a switch quantity, is DO control, can only be used for small pipe control, commonly seen in DN50 and below pipelines, rarely up.

Difference between electric valve and solenoid valve:

Solenoid valve is the magnetic force generated after the solenoid coil is energized to overcome the pressure of the spring to drive the spool action, just a solenoid coil, simple structure, cheap price, can only realize the switch;

The electric valve is driven by the motor stem, drive the spool action, and the electric valve (shut off valve) and control valve.

The shutoff valve is a two-position operation that is fully open and fully closed. The regulator is equipped with an electric valve positioner to dynamically stabilize the valve in one position through closed-loop regulation.

1. Switching mode:

Solenoid valve is driven by coil. It can only be opened or closed.

The drive of electric valve is generally with the motor, open or close action needs a certain amount of time to complete the simulation, can be adjusted.

2. Nature of work:

Solenoid valve general flow coefficient is very small, and the working pressure difference is very small.

For example, the general 25 caliber solenoid valve flow coefficient than the 15 caliber electric ball valve is much smaller.

The solenoid valve is driven through the solenoid coil, which is easy to be damaged by voltage shock.

Equivalent to the role of a switch, is on and off the two functions.

Electric valve is generally driven by the motor, voltage impact resistance.

Solenoid valve is fast open and close, generally used in small flow and small pressure, the switch frequency is large where the electric valve vice versa.

The opening of the electric valve can be controlled, the state is open, close, half open and half closed, can control the flow of the pipeline intermediary and the solenoid valve does not meet this requirement.

Solenoid valve power off can be reset, electric valve to such a function need to add a reset device.

3. Applicable process:

Solenoid valve suitable for some special process requirements, such as leakage, fluid medium special, the price is more expensive.

Electric valves are generally used for regulation, there are also switching volume, such as: fan coil end.

Selection technique

Solenoid valve selection methods can be many, but are based on the working conditions and environment of the solenoid valve and customer requirements.

Solenoid valve classification method more, such as according to the working principle to classification, according to the medium attributes to classification, according to the working conditions to classification, and according to the solenoid valve material classification.

Different types of solenoid valve selection have different methods and skills, today solenoid valve agent dry ball automation xiaobian and we talk about different types of solenoid valve selection skills.

One: corrosion resistant solenoid valve according to the fluid parameters to choose the solenoid valve: material, temperature group

1. Corrosive fluid: corrosion resistant solenoid valve and all stainless steel should be selected;

Super clean fluid: food grade stainless steel solenoid valve should be selected.

2. High temperature fluid: to choose the use of high temperature electrical materials and sealing materials manufactured solenoid valve, and to choose the type of piston structure.

3. Liquid state: large to gaseous, liquid or mixed state, especially when the diameter is larger than DN25, it must be distinguished.

4, fluid viscosity: usually below 50cSt can be arbitrarily selected, if more than this value, to choose a high viscosity solenoid valve.

Two: gas solenoid valve according to the pipe parameters to choose the solenoid valve: size specification (DN), interface mode

1. Determine the diameter (DN) of the pipeline according to the requirements of internal diameter or flow rate on site.

2. Interface mode. Generally, >DN50 should be used to select flange interface.

Three: water solenoid valve according to the pressure parameters to choose the solenoid valve: principle and structure varieties

1, nominal pressure: this parameter and other common valves are the same meaning, according to the pipeline nominal pressure to determine.

2. Working pressure: if the working pressure is low, the principle of direct action or step by step direct action must be adopted;

When the minimum working pressure difference is above 0.04mpa, direct acting, step by step, pilot can be selected.

Four: normally closed solenoid valve, usually open solenoid valve, or sustainable electrified solenoid valve

1. If the opening time is short or the opening and closing time is not much, then choose normally closed type.

2. However, for some working conditions used for safety protection, such as furnace and kiln flame monitoring, the normally open type should not be selected, but the type that can be powered on for a long time should be selected.

Five: high temperature solenoid valve electrical selection: voltage specifications should be preferred to import solenoid valve more convenient.

Six: stainless steel solenoid valve according to environmental requirements to choose auxiliary functions: explosion-proof, check, manual, waterproof fog, water, diving

1. Explosive environment: the solenoid valve of corresponding explosion-proof grade must be selected.

2, when the fluid inside the tube has backflow phenomenon, can choose with check function solenoid valve.

3, when the need for on-site manual operation of the solenoid valve, can choose with manual function solenoid valve.

4. Waterproof and dustproof varieties should be selected for outdoor installation or dust occasions (the protection grade is above IP54).

5, the fountain must be used diving solenoid valve (protection class IP68 above).

6, when the solenoid valve needs to open for a long time, and the duration of the time more than the closing time should choose the normally open type.