Description

• Complete range to meet your needs

• Simplest version of vibrators

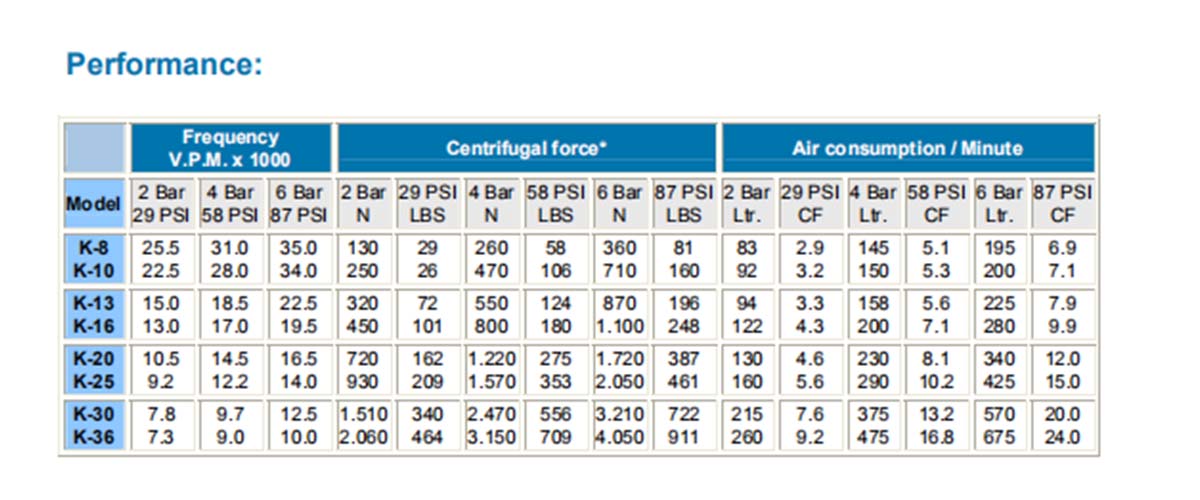

• Rotation frequency 7,000 to 35,000 RPM

• Centrifugal force 130 - 4,000 N

Advantages

· Small, Super Lightweight - aluminum housing with baked enamel paint.

· Nylon End Plates - Provide seal that prevents air leakage and keeps out environmental dust and water.

· Maintenance Free - No motor or bearings.

· No lubrication required.

· Clean Operation - No oily mist because non-lubricated air is used.

· High Frequency, Low Amplitude Vibration.

· Versatile - Easy to control force and frequency by adjusting air supply.

· Multiple Mounting Options - Two sets of bolt holes provide flexibility when mounting.

· Produces Uniform, Directional Flow.

Accessories

· Manual Valves - 2-way manual ball valve used to turn the vibrator on and off for normal operation.

· Solenoids - For remote or automated control, use 2-way normally closed solenoid valve to turn the vibrator on and off for normal operation.

· Airline Kits - Required for trouble-free operation and long life of ball vibrators. Includes airline filter and pressure regulator with gauge.

· Mufflers - Reduce noise and prevent contamination from entering exhaust port. Note: These vibrators have BSP ports. Use plastic mufflers on the BSP ports, they fit better.

· Sirometer - Convenient, compact rpm meter for measuring vibrator speed.

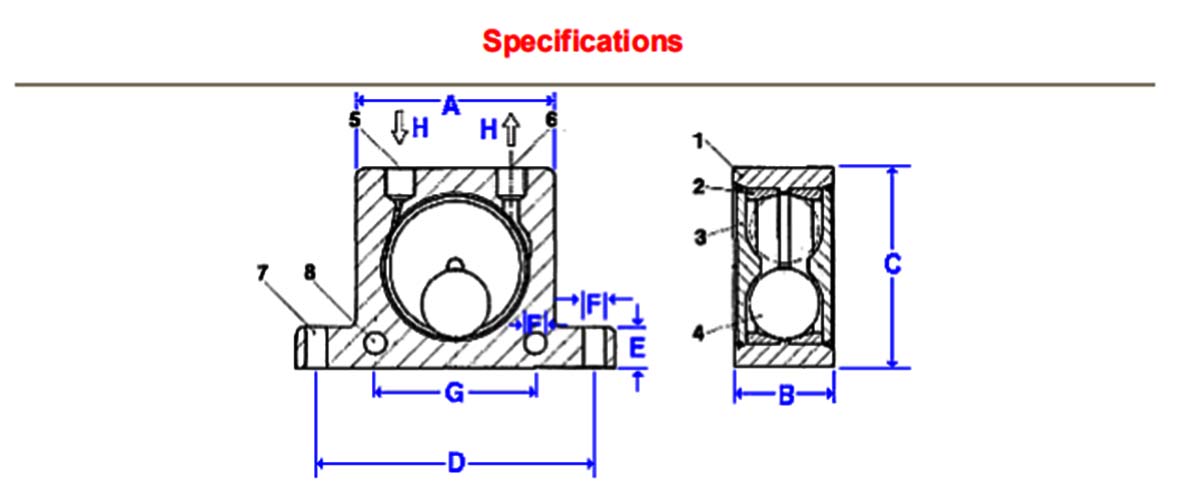

Specifications

· Filtered air - depending on size and mount orientation.

· 15 - 80 psi (1 - 5.5 bar).

· 4 - 23 cfm (113 - 651 Lpm).

· No lubrication required.

· 75 - 95 dBA with muffler.

· Force output range up to 989 force pounds (4399 N) at 80 psi (5.5 bar) based on model used.

· Frequency range up to 34,000 rpm at 80 psi (5.5 bar) based on model used.

· Operate up to 80 psi (5.5 bar) – higher psi permissible but wears unit faster.

· Maximum Ambient Temperature up to 220ºF (100ºC).

Construction:

1 - Extruded aluminum alloy body

2 - Hardened ground steel alloy races

3 - Nylon endplates

4 - Hardened lapped ball

5 - Air inlet

6 - Air exhaust

7 - Base mounting holes

8 - Lateral mounting holes