FEATURES

Noise level never exceeds 75 dba.

Bearings come pregreased, no lubrication is required.

Bearings are oversized to dramatically increase vibrators’ life.

Can be used at temperatures of up to 230 F (280 F for the GT4 & GT6) GT "S" models use unbalance weights of heavy metal (instead of the standard brass) that produces a slower frequency and a higher amplitude.

GT Series Pneumatic Turbine Vibrators are ideal for applications in the food and

pharmaceutical industries, and others involving fine, dry powders that respond well to high frequency vibration. They require no lubrication, and produce less noise than

other types of rotary pneumatic vibrators.

Standard features & benefits

Lightweight Alloy Body, powder coated to resist corrosion

Matched & shielded ball bearings pre-lubricated with long life grease

Low noise output

Low air consumption

Adjustable force and frequency

Exhaust muffler included

A few commonapplications Include:

Food Ingredient bins

PharmaceuticalIngredient bins

Weigh hoppers

Light duty vibrating tables & platforms

Small feeders

Transfer pipes

Chutes

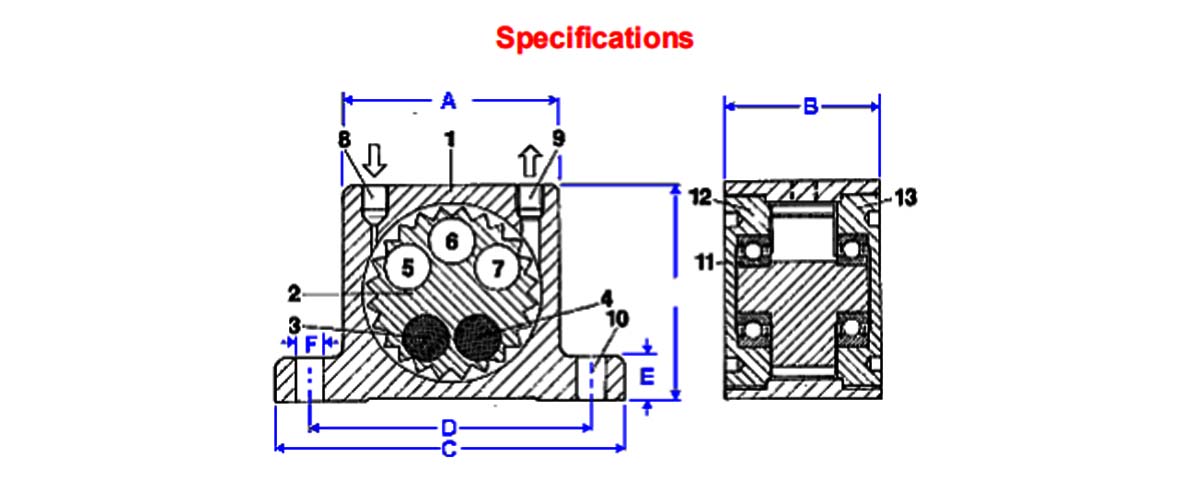

GT DESIGN

The vibration is produced by the centrifugal force of the positive and negative unbalanced moments in the rotor.

The rotor is supported on two heavy duty, prelubricated, matched shielded ball bearings.

A special long life grease ensures a long working life.

The inner and outer raceways of the bearings are designed so that the bearings can be easily replaced using only a pin-wrench.

The endplates are fitted with right- and left-hand threads and are self-locking.

Construction:

1 - Extruded aluminum alloy body

2 - Aluminum turbine wheel, hard coated

3-4 - High density mass for positive moment

5-7 - Cavities for negative moment

8 - Air inlet (BSP thread, will accept NPT)

9- Air exhaust (BSP thread, will accept NPT)

10- Base mounting holes

11- Special pre-lubricated shielded bearings

12- Hard coated aluminum end plate with left-handed thread

13- Hard coated aluminum end plate with right-handed thread

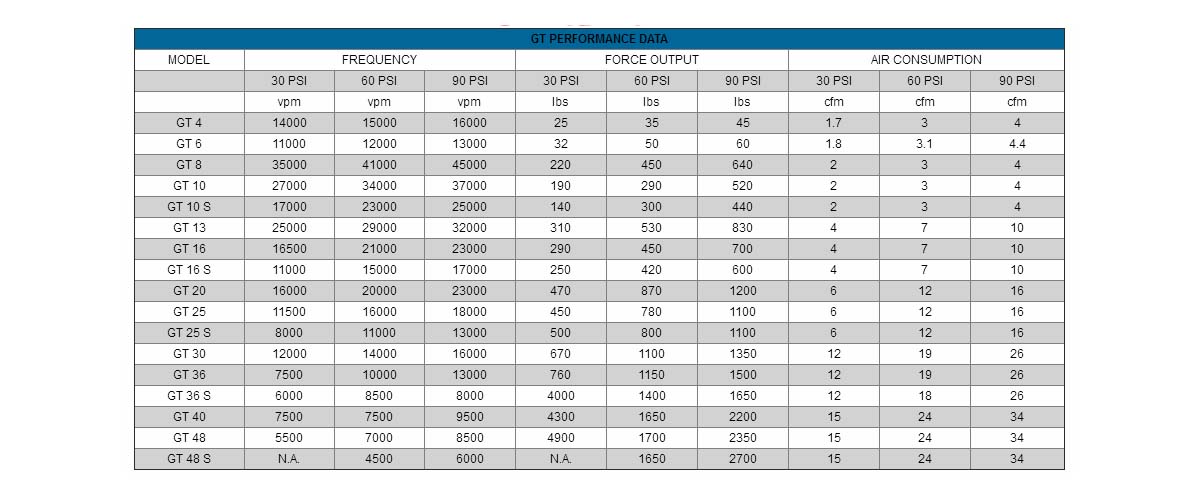

GT PERFORMANCE