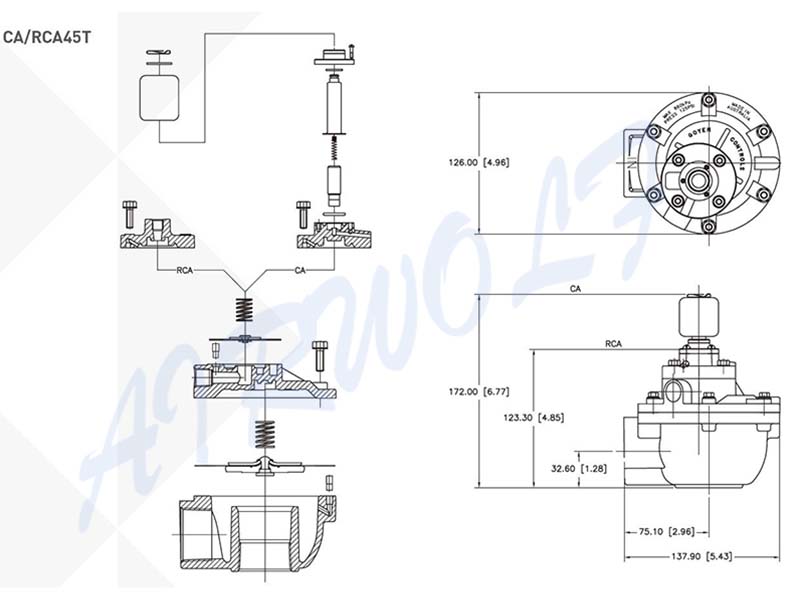

It's a high performance diaphragm valve with threaded ports. Available with integral pilot or as remotely piloted valve. Outlet at 90° to inlet. It can instantaneously open and close high-pressure gas source to generate pulses. A full range of accessory items are available including pilots, coils, diaphragm, spring.

◈Body: Aluminum

◈ Ferrule: 305 SS

◈ Armature: 430FR SS

◈ Seals: Nitrile or Viton.

◈Spring: 304 SS

◈ Screws: 302 or 304 SS

◈ Diaphragm Seat: Viton or Nitrile

◈ Before conducting any maintenance activity on the system ensure that components are fully isolated from pressure and power supplies. Pressure and power should not be reapplied until the valve has been fully assembled.

◈ Diaphragm and pilot inspection should be conducted annually.

◈Packaging Details: Standard Carton box,and other special packing according to customer's requirement.

◈Port: Ningbo/Shanghai

◈Prepare supply and blowtube pipes to suit valve specification. Avoid installing valves underneath the tank.

◈Ensure tank and pipes are free from dirt, rust or other particulate.

◈Ensure supply air is clean and dry.

◈ Mount valves to inlet pipes and blowtube to valves, ensuring no excess thread sealant can enter the valve itself.

◈Make electrical connections to solenoid or connect RCA pilot port to pilot valve (RCA valves only).

◈Apply moderate pressure to system and check for installation leaks.

◈ Fully pressurise system.

◈Test fire and listen for proper actuation and crisp pulse noise.

◈Port size: 1-1/2"

◈ Color: Slivery

◈Pressure Range: 30(5)–860(125) kPa(psi)

◈Temperature Range: Nitrile Seals: -40°C~82°C, Viton Seals: -29°C~232°C

Recommended on-time range: 50–500 ms

Recommended time between pulses: 1 minute or greater

Dust collector applications, in particular for reverse pulse jet filter cleaning and its variations, including bag filters, cartridge filters and envelope filters, ceramic filters and sintered metal fibre filters.

Copyright © 2025 LV-pneumatic. | All Rights Reserved