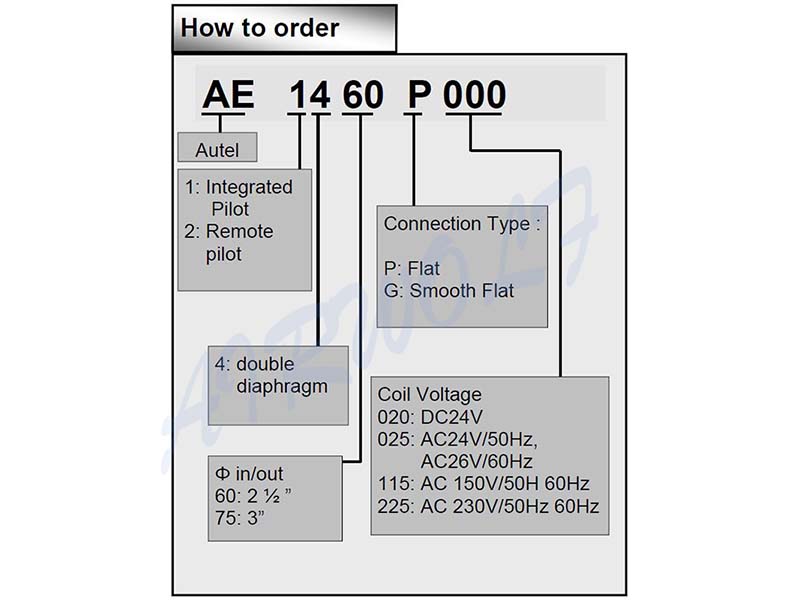

It's a normal closed double diaphragm dust removal pulse valve. These valves, used for cleaning filter elements in air filtration systems, are specifically designed for flat surfaces like square header tanks and flanged tank. Like traditional model, with threaded and coupling connection, activating divided into two types:

Integrated: Electronic control type

Remote: Air control type

A full range of accessory items are available including pilots, coils, diaphragm, spring.

◈ Valve body: Die cast aluminium

◈ Pilot: Brass

◈ Coil: Plastic

◈ Protection:IP65

◈ Seats & Seals: TPE

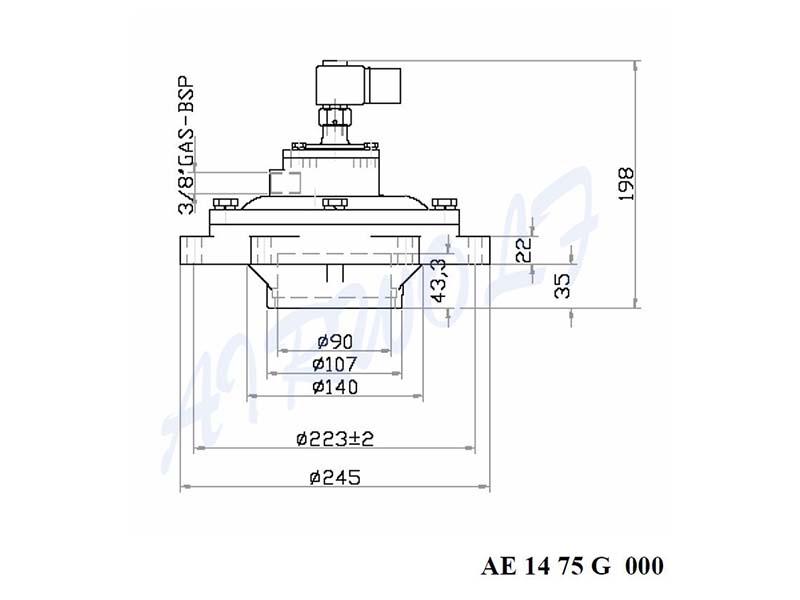

◈ Port size: 3"

◈ Control: Integrated(Electronic control)

◈ Temperature: -20 °C +100 °C

◈ Max Pressure: 8 Bar

◈ Fluid: Filtered air not lubricated

◈ Typical Applications:Dust removal equipment

◈ Spring damage. The springs on the pilot head of the pulse valve are easily damaged, which results in the long-term bleeding of the pulse valve to the nozzle.

Solution: Replace the spring.

◈ Damage of rubber pad. After using for a long time, the rubber pad on the pilot head of the pulse valve is easily damaged, resulting in the long-term bleeding of the pulse valve to the nozzle.

Solution: Replace the rubber pad.

◈Pilot dirt. Because the air intake is not clean, the fouling of the pilot is accumulated, resulting in the long-term intake of the nozzle or the pulse valve doesn't work after electrification.

Solution: Clean the pilot.

◈ Damage of diaphragm. After long-term operation, the diaphragm is easy to oxidize, resulting in leakage of the pressure relief port, and the pulse valve doesn't work.

Solution: Change diaphragm.

◈ The submerged pulse valve is directly installed on the flange seat of the outer wall of the air bag. The valve is injected across the air bag. The proper nozzle and fittings are matched according to the instructions to avoid upside down the valve at the bottom of the air bag.

◈ Tighten nut and outlet pipe.

◈ Connect the control wire to the connection seat of each electronic control valve, and pay attention to the connection port can't be upward to prevent rainwater from flowing in.

◈ Ensure that the compressed air supply is clean and dry. Provide proper air pressure to the air bag system and check for installation leaks.

◈ Test the injection sequence of submerged pulse valves, and hear whether all pilot valves are operating properly, and whether the sound of pulse injection is clear and crisp.

Copyright © 2025 LV-pneumatic. | All Rights Reserved