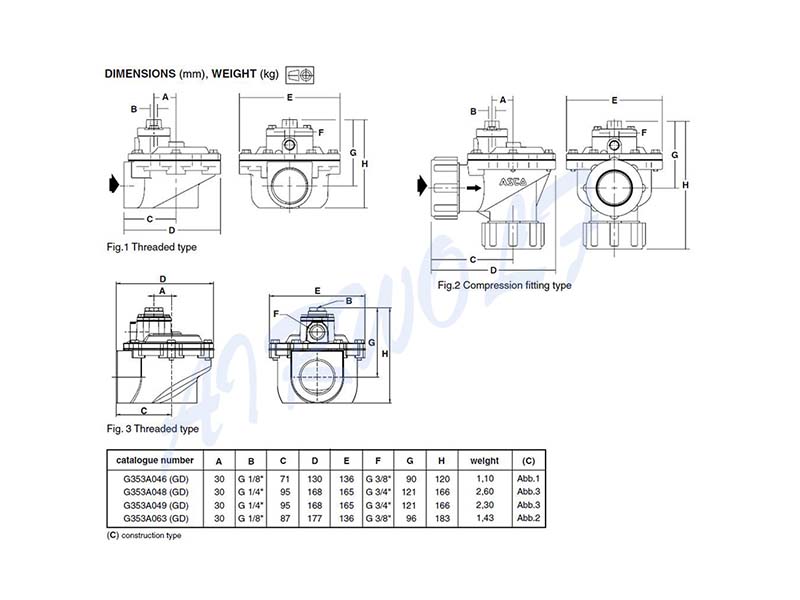

It's a normal closed double diaphragm dust removal pulse valve. These valves, used for cleaning filter elements in air filtration systems, are specifically designed for flat surfaces like square header tanks and flanged tank. Like traditional model, with threaded and coupling connection, activating divided into two types:

Integrated: Electronic control type

Remote: Air control type

A full range of accessory items are available including pilots, coils, diaphragm, spring.

◈The high flow, angle type bodies in combination with the special main diaphragm assemblies give the unique operating features required for dust collector service applications.

◈ Integral compression fittings for fast, easy, secure installation.

◈ Valves can be supplied according to ATEX Directive 2014/34/EU for non-electrical equipment.

◈ The components satisfy all relevant EC directives.

◈ Valves can also be supplied with Viton diaphragms and seal materials. Use the appropriate optional suffix letter for identification.

◈ Sequential controller for pilot solenoid valves.

◈Pilot boxes containing 2 to 12 pilot solenoid valves.

◈ Pilot solenoid valves can be equipped with explosionproof solenoids for hazardous locations according to “ATEX” and national standards.

◈Packaging Details: Standard Carton box,and other special packing according to customer's requirement.

◈Port: Ningbo/Shanghai

◈When connecting piping or tubing to the G1/8 or G1/4 connection in the valve bonnet, the remote ASCO pilot valve should be mounted as close as possible to the main pulse valve. Connection tubing lengths of 3 meter or less have little effect on the pulse response. Installations with over 3 meter of tubing must be tested under actual operating conditions. Tubing with Φ6 or Φ8 mm O.D. is recommended for all installations.

◈ For compression fitting types tightness is achieved by the co mpressed gasket on the blow tube.

◈ Other pipe threads are available on request.

◈ Installation/maintenance instructions are included with each valve.

◈ Port size: 2"

◈ Differential pressure: 0.35 - 8.5 bar [1 bar = 100kPa]

◈Ambient temperature range: -20~85°C

◈ Fluids: Air

Copyright © 2025 LV-pneumatic. | All Rights Reserved